Essential Test and Tag FAQs

Test and Tag refers to the process of inspecting and testing electrical appliances and equipment to ensure they are safe to use, followed by labeling them with a tag that indicates the test results and the next testing date. This is crucial for workplace safety and legal compliance.

The process typically involves:

Visual Inspection: Checking for obvious faults or damage to the appliance or equipment.

Electrical Testing: Using specialized equipment to check if the appliance is functioning correctly and is electrically safe.

Tagging: A tag is attached to the equipment, displaying the date of the test, the next test due date, and the test result (whether the equipment passed or failed).

Test and Tag services are typically required in workplaces, schools, and public spaces to ensure the safety of staff and the general public from electrical hazards. It’s often mandated by occupational health and safety regulations in many countries.

We are a professional Test and Tag company dedicated to ensuring the safety and compliance of your electrical equipment. Our services include Three Phase Testing, Cord Repair and Replacement, Microwave Testing, RCD Testing, Electrical Thermal Imaging, and Fire Extinguisher Testing.

We work with businesses and residential clients to provide expert solutions that protect both people and property from electrical hazards.

Our team consists of certified, experienced professionals who follow strict industry standards and safety protocols. We use advanced testing equipment and provide detailed reports after each inspection to ensure your equipment is compliant and safe.

We also stay up-to-date with the latest safety regulations to ensure our services always meet current standards.

What sets us apart is our commitment to customer satisfaction and safety. We take the time to fully understand your needs and tailor our testing services accordingly. Our team is highly trained, and we provide fast, reliable, and efficient service.

Additionally, we offer ongoing support and clear communication, ensuring you are always informed about the status of your equipment.

Our testing process begins with a thorough assessment of your equipment to ensure it meets all safety requirements. After testing, we provide each item with a visible tag that indicates whether it passed or failed the inspection.

If an item fails, we’ll advise you on necessary repairs or replacements and offer our repair services if needed. We also provide a detailed report for your records and compliance.

Getting started is easy! Simply contact us via our website or phone to schedule a consultation. We’ll discuss your needs, provide a quote, and arrange a time to visit your location. Our team will then carry out the necessary tests and provide all the necessary documentation to ensure your equipment is safe and compliant.

We’re here to make the process as simple and hassle-free as possible!

We proudly offer our Test and Tag services across the whole of New Zealand. Our experienced technicians are available to work in various regions, including Auckland, Wellington, Christchurch, Hamilton, and Dunedin.

No matter where you are in the country, we’re equipped and ready to provide reliable testing and safety solutions for your electrical equipment.

Single Phase Testing

Single Phase Testing refers to the process of inspecting and testing electrical equipment that operates on a single-phase power supply to ensure it meets safety standards. During single-phase electrical testing, specialized tools are used to check for potential hazards, including faulty wiring, improper grounding, or insulation issues. The test helps identify any electrical faults that could pose risks such as electrical shocks, fires, or equipment malfunctions.

By conducting single-phase electrical testing, businesses and homeowners can ensure the ongoing safety and reliability of their electrical appliances. This process is crucial for compliance with electrical safety regulations, such as those outlined in the AS/NZS 3760 standard in Australia/NZ

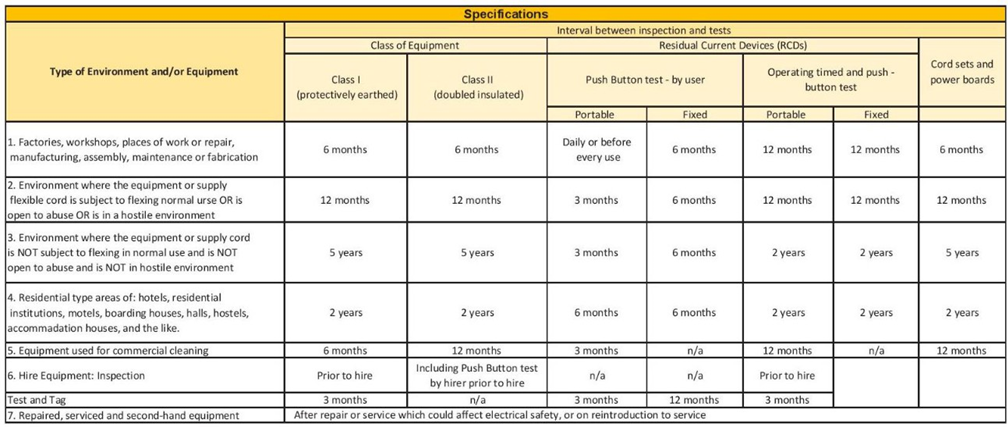

The frequency of single-phase testing depends on the environment in which the equipment is used and local safety regulations. Generally, it’s recommended to test single-phase electrical equipment at least once a year in a commercial setting, while residential equipment might require testing every 2-5 years, depending on the risk level.

For workplaces, industries, or construction sites, electrical testing may be required more frequently, with some regulations mandating testing every 6 to 12 months. The key is ensuring that electrical safety is maintained, reducing the risk of equipment failures, electrical hazards, or even potential injuries.

During a single-phase test, the following key factors are examined to ensure that the electrical equipment is functioning safely:

-

Insulation Resistance: Tests whether the insulation is effective, preventing current leakage that could lead to shocks or fires.

-

Earth Continuity: Checks the grounding of the equipment to ensure that if a fault occurs, the electrical current will be safely directed to the ground.

-

Polarity Test: Verifies that the wiring is correctly installed to prevent any reverse polarity issues that could damage the equipment.

-

Leakage Current: Assesses whether any current is escaping through the insulation, which could indicate a fault or safety risk.

These tests are performed to meet the standards of electrical safety and to ensure that all equipment operates efficiently without posing a hazard.

Yes, single-phase testing is essential for most electrical appliances, especially in commercial or industrial environments. All electrical equipment, from basic home appliances to complex industrial machines, should undergo regular safety testing to ensure they meet safety standards.

However, single-phase testing is particularly critical for portable or movable equipment, such as power tools, computers, and kitchen appliances, as they can be more prone to wear and tear that may compromise electrical safety. Regular test and tag services ensure that these devices are thoroughly checked and compliant with local safety regulations, such as those outlined in AS/NZS 3760 (Australia/NZ)

Single-phase testing and three-phase testing differ primarily in the type of electrical system being tested.

-

Single-phase systems are commonly used in residential homes and small businesses where the electrical demand is relatively low. These systems deliver power through two wires—live and neutral—and are tested for insulation resistance, grounding, and leakage current.

-

Three-phase systems, on the other hand, are used in larger commercial or industrial setups where higher electrical loads are required. Three-phase testing is more complex and involves testing all three phases of power distribution to ensure balance, stability, and safety.

While both tests are critical for ensuring electrical safety, single-phase testing is typically quicker and simpler, focused on the basic safety of lower-demand equipment.

It is strongly advised that single-phase testing be carried out by a licensed professional or an experienced technician. While some basic visual inspections can be done by homeowners, testing electrical systems requires specialized equipment and knowledge of local regulations.

Inaccurate testing or using the wrong methods could lead to unsafe conditions, which may put you at risk of electrical hazards. A qualified professional will have the necessary training to carry out all required tests, including insulation resistance, earth continuity, and leakage current, ensuring that all equipment meets safety standards and regulations.

For proper compliance, it’s important to rely on certified test and tag services.

If your single-phase equipment fails the safety test, the test and tag technician will typically advise on the necessary repairs or replacement needed to bring the equipment up to code.

Failure can occur for several reasons, such as damaged insulation, improper grounding, or faulty wiring. Once the failure is identified, the equipment must either be repaired or removed from service until it meets the safety standards. It’s crucial to address any failure immediately, as continued use of faulty equipment could result in electrical hazards, such as electric shocks, fires, or equipment damage.

In some cases, the technician may place a “Failed” tag on the equipment, indicating it is no longer safe for use until repaired and re-tested.

For business owners, regular single-phase electrical testing provides numerous benefits, including:

-

Improved Safety: Regular testing ensures that your equipment is electrically safe, reducing the risk of accidents, fires, or injuries.

-

Compliance: By following local regulations and performing regular tests, businesses can avoid fines or penalties related to non-compliance.

-

Reduced Downtime: Preventing equipment failure through regular testing helps minimize disruptions to your operations, saving both time and money.

-

Cost Efficiency: Regular testing can detect minor issues before they become major problems, reducing repair and replacement costs over time.

By investing in test and tag services, businesses can ensure the ongoing safety and compliance of their equipment while promoting a safe work environment.

The duration of a single-phase test can vary depending on the type and number of appliances or equipment being tested. On average, each device can take anywhere from 5 to 15 minutes to test. However, for larger setups or when testing multiple devices, the process could take several hours.

Factors influencing the test time include the type of equipment, accessibility, and whether any issues are found that require additional checks. Professional test and tag services will aim to minimize downtime while ensuring that each piece of equipment is thoroughly tested and tagged according to safety standards.

The cost of single-phase testing services can vary depending on the location, the type of equipment being tested, and the number of devices you need to check. Starting from $1.99/- per item for standard test and tag services, with additional charges for travel or specialized testing.

For larger businesses or installations with a high volume of equipment, you may receive discounts or package pricing. It’s important to consider the value of investing in regular testing to avoid the costs of equipment failure, legal liabilities, or workplace injuries. Always ensure that the test and tag provider is certified and follows local regulations to guarantee the quality and reliability of the service.